Long ago, machines were there to aid humans in production. Today, it’s the opposite. Humans give aid to machines. This allows manufacturers to increase their productivity, efficiency, and profits while reducing costs from having to hire new employees. Manufacturers incline toward the trends and latest innovations to get rid of the old and less efficient and pave the way for the new that works.

And this isn’t just for the manufacturing tycoons, which, with an ever-evolving approach, gets a high survival rate in the industry. The same way goes for small businesses. They should also focus on improving their productivity as much as their huge counterparts do. Here are ways both the small and big manufacturers can improve their output production and reap its relevant benefits:

Examine your current workflow

Of course, you won’t be able to improve your present workflow if you don’t examine it first, particularly in three areas—labor, processes, and equipment and technology. Evaluate your current employee performance, the issues in your processes, and all the equipment you are using. It’s time you check if all your machines work well.

Schedule the maintenance

Don’t take equipment maintenance lightly. You never know when breakage happens, and when they do, they automatically slow down the manufacturing process. Maintenance may reduce the output within the schedule, but fixing the breakage means downtime, resulting in more loss. Hence, the best that you can do is train your operators to do regular preventive maintenance on all equipment, ensuring that all schedules don’t get delayed.

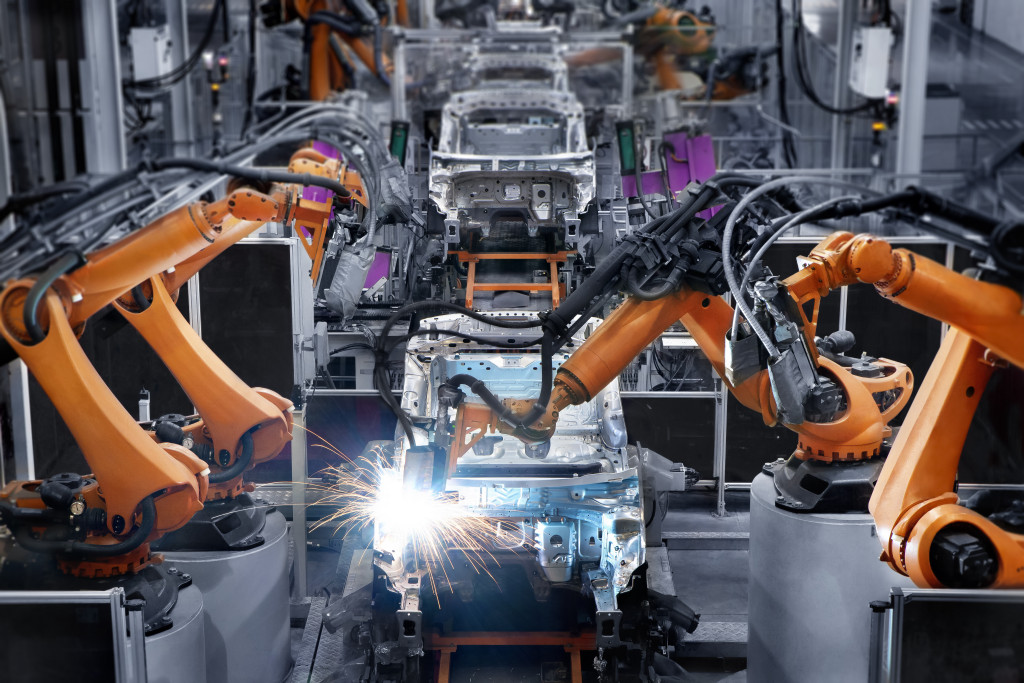

Invest in new technology and processes

There are plenty of new technologies and methods designed to speed up the manufacturing process. Get rid of the outdated methods and equipment and take advantage of the automation process. One worthy investment is a large part injection molding machine that allows you to produce your goods en masse.

Reducing material waste can help you decrease the overall manufacturing costs. Small or large part injection molders can lead to a lower scrap rate. If you go for repetitive outputs to emphasize your brand, this is your practical choice. You can rely on its production consistency. Explore other modern technologies too.

Remove all unused machinery

As you focus on the new manufacturing trends, take old machine removal seriously. These machines can still drag your productivity down as they lie around cluttering the spaces. You may even continue to spend for their maintenance even when you’re not making any profits out of them.

Organize everything

Removing all those old machines doesn’t mean you need more space for work movement. It’s the other way around. Reducing movement in the workplace can maximize task efficiency since excess movement means poor organization. After removing all the unused tools, machines, and materials, create organized storage so that employees don’t spend much time finding items.

As much as possible, reduce your employees’ distance and travel time. Find ways to shorten the distance between machines or products to increase production time.

Train employees

Prioritize educating your employees, such as about their safety. Take the time to train your employees on how to use the new technology and equipment. This allows you to get the most value out of these machines while you get to retain your employees. Once you install new machines, schedule the training sessions and even refreshers.

Continuous training is crucial since technology evolves quickly. When operators are properly trained, you will not get issues of a labor shortage since even a few, but well-trained employees can do the job of so many.

Transform how you stock up on inventory

For instance, a baking company is in the process of manufacturing its goods yet runs out of flour in the midst of it. This can significantly delay the production process. To meet the demands of production, make sure that you have a steady and balanced supply of inventory. Take note that you don’t need to have too many stocks on hand. Being smart about inventory stocking means keeping your supplies adequate.

Encourage teamwork and communication

Even if your manufacturing company relies heavily on machines, your employees are the ones operating or aiding them. No matter the industry, teamwork and good employee relations are crucial. Make an effort to encourage communication in your employees, especially soliciting their views about your processes. They should have an avenue to express themselves and get to know their other co-employees.

Manufacturing methods and technology will continue to evolve. Make sure that you get into the motions to scale your manufacturing business alongside many other manufacturers.